Protective Coating

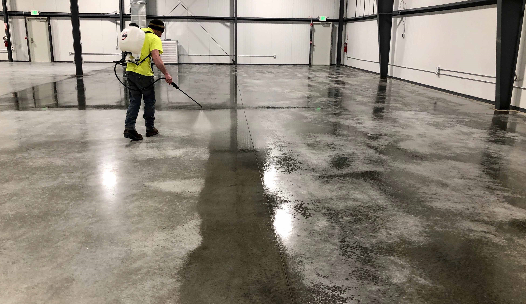

Protective Coatings are applied to the surface of an object, typically referred to as the substrate, and form an essential part of the finished product. In many cases, coatings improve the surface properties including adhesion, appearance and corrosion or wear and scratch resistance.

Anti-Carbonation coatings are surface treatments that have a high resistance to carbon dioxide. They protect concrete from carbonation by acting as a carbon dioxide barrier. The elastic properties of some manufactures products allow for an amount of movement and crack bridging.

Corrosion resistant coatings protect metal components against degradation due to moisture, salt spray, oxidation, or exposure to a variety of environmental or industrial chemicals in a range of industries.

Water sealers seal the entire surface of the masonry with a thick, continuous barrier. Paint is a common example of a water sealer. These products cover any holes or cracks in the bricks or mortar; while this keeps water from getting in, it also prevents water and gas from getting out. Because of the continuous barrier they form, water sealers prevent the bricks from being gas permeable as well as trapping existing moisture inside the bricks. This can cause deterioration from the freeze thaw cycle to continue even though the chimney has been waterproofed.

Unlike sealers, water repellents penetrate into the masonry, coating the cracks, holes, nooks, and crannies of the bricks and mortar. By doing this, a continuous barrier is not formed but the masonry is still protected against water. This allows trapped water to evaporate while the masonry stays gas permeable.

Anti-Carbonation Coating

Corrosion Resistant Coating

Water Repellent & Sealers